3 Manufacturing Details You Can Achieve With Vericut Software

In the ever-evolving landscape of manufacturing, maintaining precision and efficiency is paramount. Whether you're producing complex aerospace parts or everyday consumer goods, the role of technology in fine-tuning manufacturing details cannot be overstated. Enter Vericut Software, a powerful tool that helps streamline and optimize the production process. Vericut is designed to simulate CNC machining in a virtual environment, offering a detailed analysis that empowers manufacturers to enhance their production capabilities. In this blog post, we'll explore some of the most impressive manufacturing details that can be achieved using Vericut Software from a Vericut reseller.

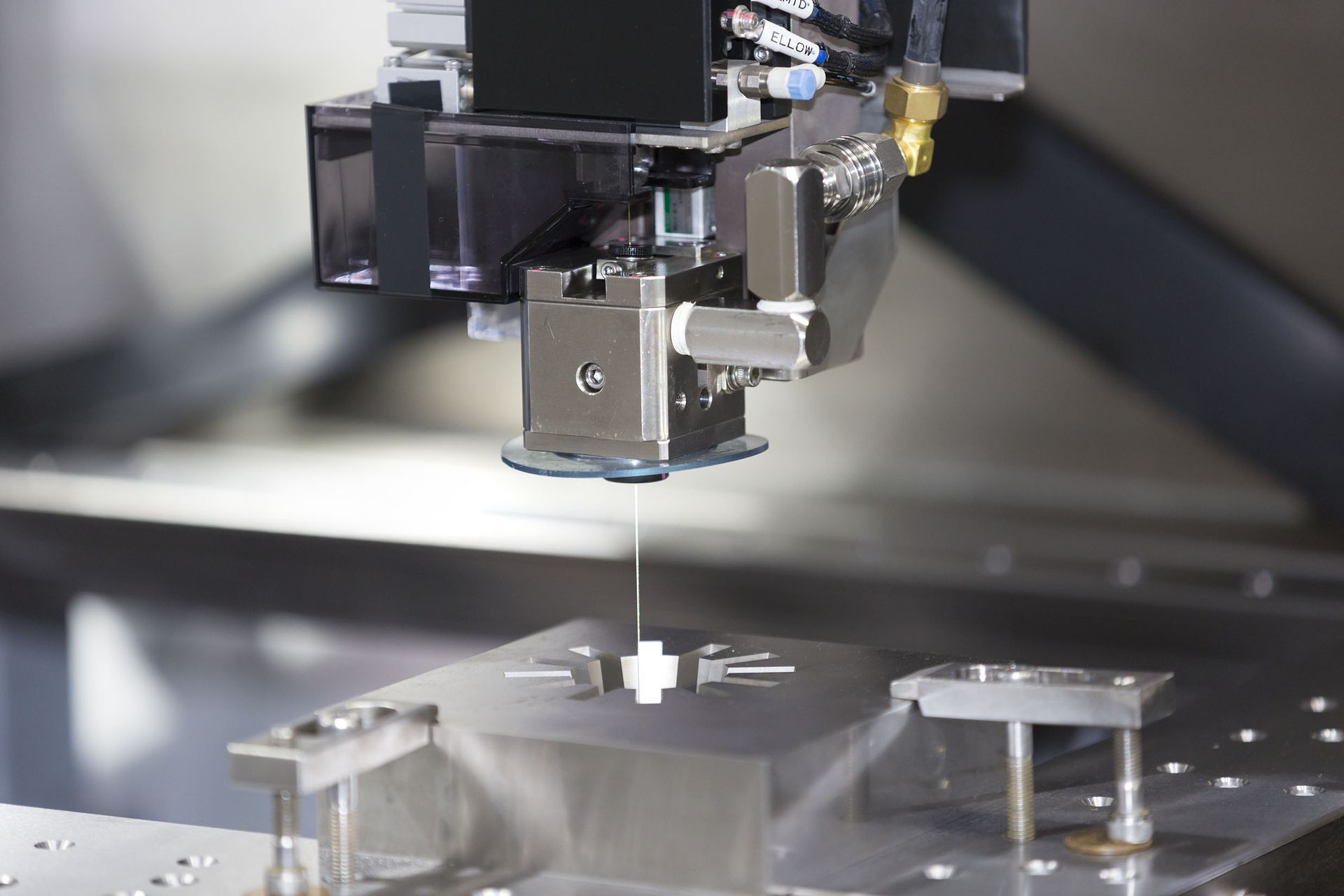

1. Accurate CNC Machining Simulations

One of the most significant capabilities of Vericut is its ability to perform accurate and reliable simulations of machining processes before actual production. This virtual simulation aids manufacturers in identifying potential errors and interferences that could arise during machining. By allowing users to visualize how their CNC code will affect the workpiece, Vericut minimizes costly mistakes, ultimately leading to higher efficiency and better quality outcomes. Such simulations have proven invaluable to thousands of companies, universities, and government agencies across more than 55 countries, according to CGTech.

2. Optimization of CNC Operations

Beyond simulation, Vericut shines in its optimization features, which are essential for enhancing manufacturing productivity. The software offers a suite of tools designed to improve the efficiency of CNC operations by adjusting feed rates, optimizing tool paths, and reducing cycle times. These optimizations not only lead to quicker turnarounds but also extend the lifespan of tools and machinery, saving businesses significant costs over time. By employing Vericut, manufacturers can achieve a delicate balance between speed and precision, essential factors in today's competitive manufacturing sectors.

3. Comprehensive Verification and Quality Control

Additionally, Vericut provides comprehensive verification and validation solutions that are key to maintaining stringent quality control. Manufacturers can use the software to verify the accuracy of their CNC programs, ensuring that the final products meet exact specifications without deviations. This attention to detail is critical, especially in industries where precision is non-negotiable, such as aerospace and medical device manufacturing. Vericut's robust verification process helps maintain high standards of quality, thereby building trust with clients and end-users alike.

In conclusion, Vericut Software is a crucial asset for any manufacturing enterprise that prioritizes precision and efficiency. Its extensive features, including simulation, optimization, and verification, provide users with the tools needed to refine their manufacturing processes and achieve exceptional results. With global utilization and recognition, Vericut continues to be an indispensable tool in the industry, continually pushing the boundaries of what can be accomplished in the manufacturing sector. Looking for a

Vericut reseller? Call us at Sierra Cad/Cam, Inc.

Share On: